SWD brush polyurea anticorrosion coating

The coating is cured by the reaction and absorption with air moisture and has high adhesive strength with substrate. It is containing large amount of urea bond, biuret bond, urethane bond and hydrogen bond to get excellent physical properties and anticorrosion performance. It has high properties of acid resistance, alkali resistance, salt and water resistance, temperature variation and chemical resistance properties. One component polyurea is easy to apply without polyurea spray machine. The regular roller or brush or airless sprayer is available. The service life can reach above 25 years if strictly confirm the regular application standard.

Specifications

Adhesive strength (concrete base) 3.5 Mpa( or substrate broken)

Adhesive strength (steel base) 10.6Mpa

Impact strength ≥50kg•cm

Tensile strength 18.5Mpa

Elongation 450%

Temperature variation -40------+180℃

Wear resistance (700g/500r) 7.3mg

Acid resistance (50%H2SO4 or 15%HCI, 30d) no rust no bubbles no peel

Alkali resistance 50%NaOH, 30d no rust no bubbles no peel

Salt resistance 60g/L, 30d no rust no bubbles no peel

Salt spray resistance 2000h no rust no bubbles no peel

Oil resistance 0# diesel crude oil 30d no rust no bubbles no peel

Data of performance

Color Multiple colors as customers’ need

Luster glazed

Density 1.03g/cm3

Volume solid content 78%±2%

VOC 153g/L

Recommended dry film thickness 100-200μm

Theoretical coverage 0.13kg/sqm (calculated by the above solids percentage and dry film thickness of 100 microns)

Practical coverage Allow appropriate loss rate

Dry time 1-3h

Overcoating interval min: 3h, max: 28h

Overcoating method Airless spray, Air spray, Brush, Roller

Flash point 59℃

Recommend procedures

No. | Name of products | Layers | Dry film thickness(μm) |

1 | SWD polyurea special primer | 1 | 80 |

2 | SWD one component polyurea coating | 1 | 80 |

3 | SWD one component polyurea coating | 1 | 50 |

Total | | 3 | 210 |

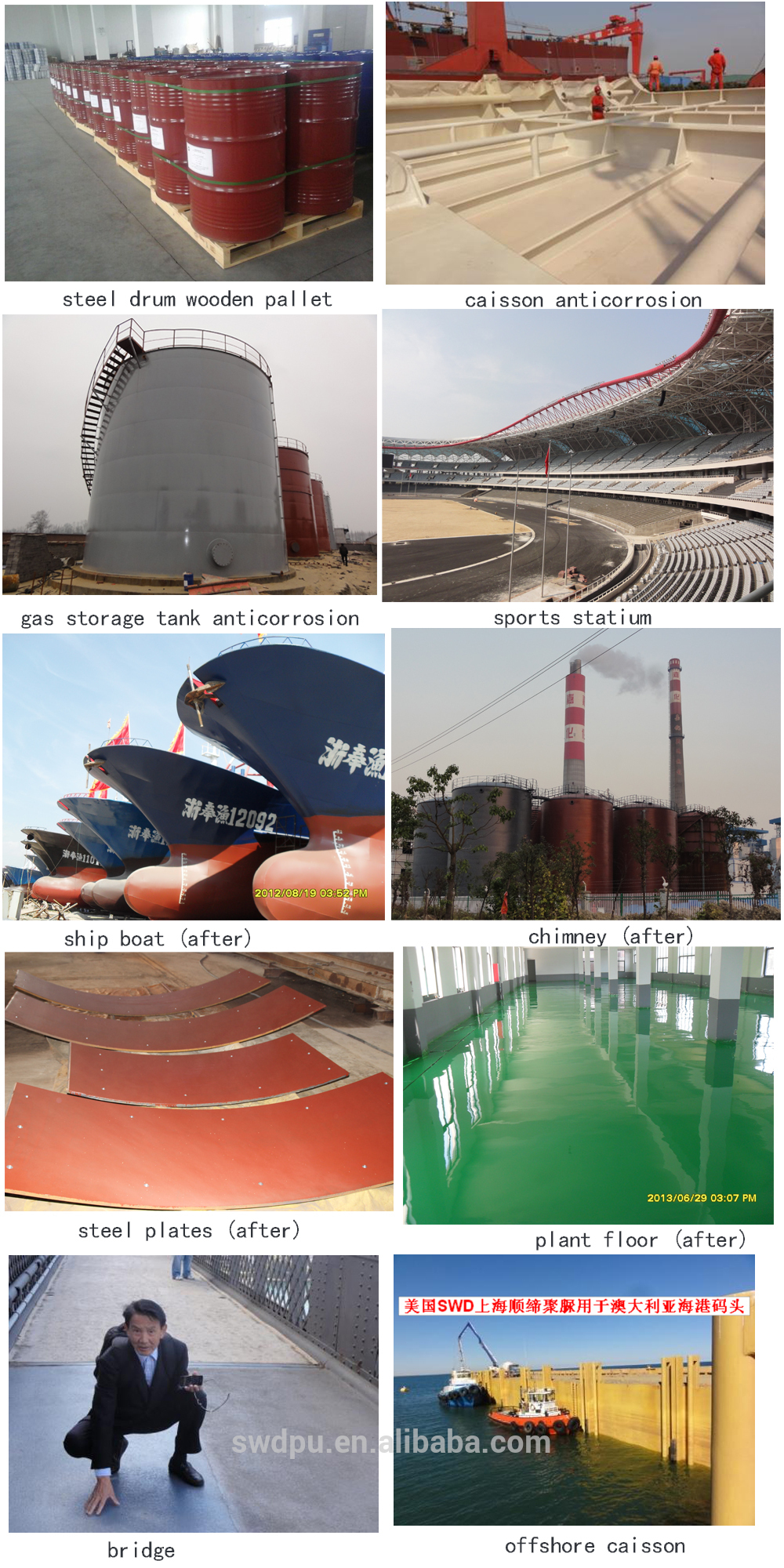

Application scopes Anticorrosion and waterproof protection of petroleum, chemical industry, transportation, construction, electricity, container and other industries.

application pic. (brushing)

poly urea coating usage on pipelines pic.

poly urea coating usage on pipelines pic.

Company Information

SWD Polyurethane (Shanghai) Co., Ltd. is invested & established by SWD Urethane Co., USA in China. It has set up his manufacturer base and technology R & D laboratory for spray Polyurethane Polyurea anticorrosion, waterproofing and insulation series products and sales center. We deliver full service in all aspects of anticorrosion waterproof insulation circle of industrial commercial and residential field, including two pack spray polyurea and single component brushable polyurea coating, self-leveling polyurea polyurethane coating, polyurethane foam, etc. We are top 3 polyurea professional manufacturers in China.

FAQ

1.We are factory.

SWD New Material (Shanghai) Co., Ltd is a professional manufacturer of polyurea polyurethane coating and pu foam in China, with headquarter in US for over 40 years. We have our own production workshops focusing on all aspects of anticorrosive waterproof, insulation fields. US technology and made in China, high quality and nice prices.

2.OEM is accepted ?

We have our own R&D team and specialists, so we can customize the product that customer’s require.

3.How to guarantee the high quality?

We have the ISO9001 quality management system certificate, we are PDA member and have standard test reports. We strictly implement the rules according to the quality standard in every aspects from the purchase of raw material to the production process and outgoing of products.