0086-21-51905316

3rd Floor, No. 38, Lane 1688, Lianhang Rd., Minhang District, Shanghai, China (Mainland)

| Quantity(Kilograms) | 1 - 200 | >200 |

| Est. Time(days) | 7 | To be negotiated |

The reinforced concrete structures in the municipal engineering will crack on the surface because of the thermal expansion and cold contraction influence, and then the humidity from salt spray, acid rain, oxygen of air will rust the concrete gradually along with the cracks. When the erosion deeps down the reinforced concrete internal structure and destroy its construction property over time, the capability and construction strength of reinforced concrete structure will be change and weak. It will even risk the livelihood security of the resident. The water base municipal engineering special reinforced concrete anticorrosion coating is developed by SWD Urethane Co., USA in the 1990s, the coating film is dense, flexible, effectively protect the concrete from crack and corrosion. It has been widely applied in the reinforced concrete structures protection projects in the Europe, America and the East Asia regions.

Characteristics

Applied with unique formula, taking one component environment friendly water base polymer and high quality nano materials as main raw materials, this product is refine produced from scientific process that has UV stable monomer structure and special functional groups of high adhesive strength and anticorrosion protection. The coating film is dense, with excellent sealing and anti-permeability performance and high adhesive strength with substrate, high properties of acid and alkali and oil resistance, salt spray resistance and waterproof, anti-mildew as well as chemical resistance. One component water base product, easy to apply, green and eco friendly, with no harmful violate gas during application. It is environment friendly product that will do no harm to environment and human health.

Specifications

State in containers no blocks after mix, uniform

Performance convenient in 2 layers

Appearance normal

Covering rate (white or light color a)/ (g/m2) ≤ 150

Dry time/h tack free time≤4, solid time≤24

Fineness b/um ≤60 (except flake pigments)

Acid resistance c (5% H2SO4) 168h normal

Salt spray resistance 1000h no bubbles, no peel off

Adhesive strength (grid method)/class ≤1

Bending resistance/cm ≤2

Impact resistance/cm ≥30

Tensile strength ≥2.0Mpa

Elongation ≥150%

Temperature variation (5 circles) -40℃ ~ +120℃

Storage stability crust /class≥ 8; settling/class ≥6

Artificial weathering resistance 1000h no bubbles, no peel off, no crack

(white or light color a, d) pulverization≤1 class; color changing≤2 class

Data of performance

Color Multiple colors as customers’ need

Luster half glazed

Density 1.22g/cm3

Volume solid content 62% ±2%

VOC 18g/L

Recommended dry film thickness 100-200μm

Theoretical coverage 0.18kg/sqm (calculated by the above solids percentage and dry film thickness of 100 microns)

Practical coverage Allow appropriate loss rate

Curing mechanism room temperature cure

Tack free time 1-3h

recoating internal min: 3h, Max: 26h

Overcoating method airless spray, air spray, brush, roller

Flash point no flammable, no explosive, safe and Eco friendly

Recommended procedures

No | Name of the products | Layers | Dry film thickness (μm) |

1 | SWD water base environment friendly anticorrosion primer | 1 | 30 |

2 | SWD water base reinforced concrete anticorrosion coating | 1 | 60 |

3 | SWD water base reinforced concrete anticorrosion coating | 1 | 60 |

Total |

| 3 | 150 |

Application scopes Anticorrosion protection of reinforced concrete structures of multicipital construction projects, tunnel projects, traffic and mining projects etc.

Shelf life 12 months (Indoor with dry and cool conditions, frozen below 0℃)

Packing 20kg/bucket, 25kg/bucket

SWD Polyurethane (Shanghai) Co., Ltd. is invested & established by SWD Urethane Co., USA in China. It has set up his manufacturer base and technology R & D laboratory for spray Polyurethane Polyurea anticorrosion, waterproofing and insulation series products and sales center. We deliver full service in all aspects of anticorrosion waterproof insulation circle of industrial commercial and residential field, including two pack spray polyurea and single component brushable polyurea coating, self-leveling polyurea polyurethane coating, polyurethane foam, etc. We are top 3 polyurea professional manufacturers in China.

1.We are factory.

SWD New Material (Shanghai) Co., Ltd is a professional manufacturer of polyurea polyurethane coating and pu foam in China, with headquarter in US for over 40 years. We have our own production workshops focusing on all aspects of anticorrosive waterproof, insulation fields. US technology and made in China, high quality and nice prices.

2.OEM is accepted ?

We have our own R&D team and specialists, so we can customize the product that customer’s require.

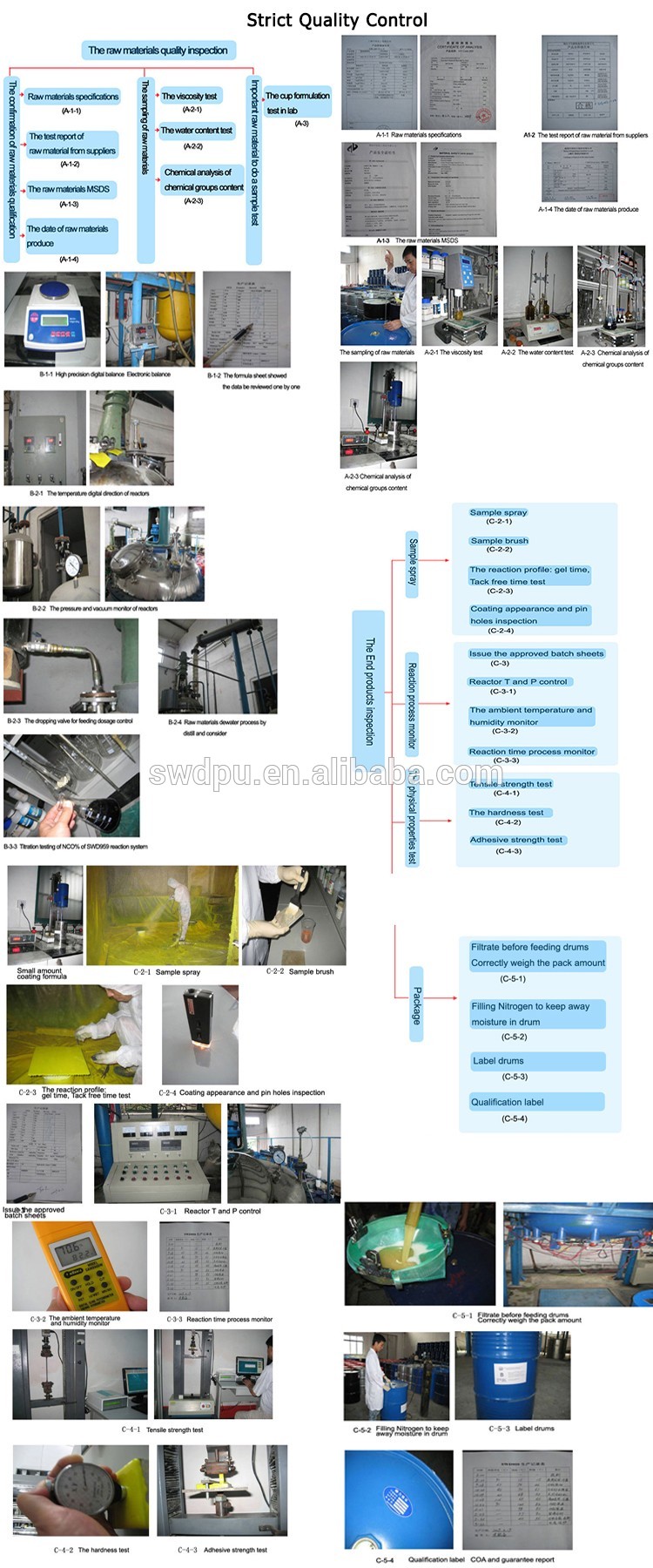

3.How to guarantee the high quality?

We have the ISO9001 quality management system certificate, we are PDA member and have standard test reports. We strictly implement the rules according to the quality standard in every aspects from the purchase of raw material to the production process and outgoing of products.